enTIRE Retread Factory Management

Improve production, reduce costs

Overview

enTIRE Retreading is a version of the enTIRE Tyre Management System that has been specifically designed to manage retreading operations. The system tracks individual tyres throughout the factory process using RFID Tags. Tyres are logged in and out of each station, while updating a central information store so the factory processes can be monitored and controlled from a central location. Multiple factories can be connected and controlled by the system with large wall displays of each station and process.

Screen displays and input at each station is linked to a central system that centralises and monitors every aspect of a retreading factory.

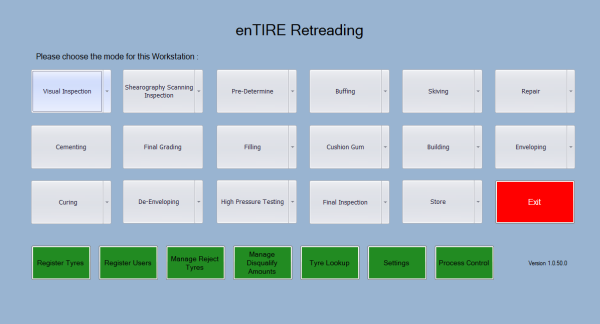

Figure 1 – enTIRE Retreading front screen.

Casing tracking by RFID

Casings are tracked through the factory processes from delivery and initial inspection to the return of the final product to the customer. Casings are scanned into and out of each station so the exact process time at each station and the workers performance can be calculated. The benefits of using RFID include:

- Reusable inexpensive RFID tags

- Accurate, efficient

- Detailed tyre processing information

- Detailed production worker performance information

- Real time access to the factory process

- Real time reporting

- Comprehensive worker incentive system

Casing Evaluation and Management

Casing quality and damage is evaluated and updated throughout the retreading process. Data received from each station is used to constantly update the rating of each casing. Casing information includes:

- Incoming casing brand mix information

- Incoming casing size information

- Incoming casing width information to brand and type

- Incoming casing life information

- Incoming casing grading information

- WIP casing information

- Product (Casing) reject rate

- Rework statistics

- Failure rate in each station

Worker performance

Worker performance is monitored and updated to allow the payment of incentives, experience and qualification. Workers not qualified to work at a particular station cannot log onto that station. Many aspects of a workers performance is analysed including:

- Worker daily performance achievement versus target

- Worker monthly performance achievement versus target

- Worker accumulated processing time efficiency versus target

- Worker failure rate monitoring

- Worker incentive reporting

- Cost by station by worker reporting

- Total casing labour cost tracked

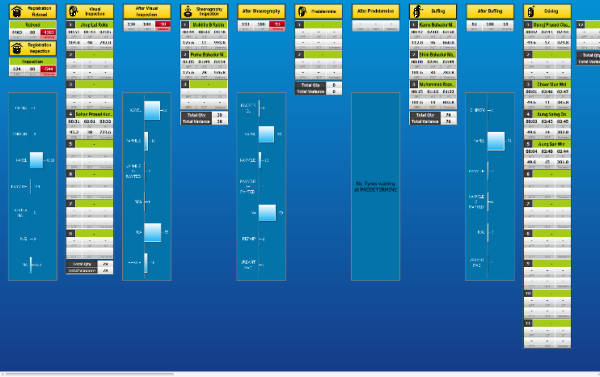

Figure 3 – enTIRE Retreading station login screen.

Station performance

Since enTIRE tracks the time each casing arrives and leaves a station, performance statistics, operator statistics, bills of material and stock levels between stations can be calculated. Individual Station information include:

- Performance by hour and shift

- Monthly performance

- Processing time efficiency

- Utilization information

- Management flow plan by day

- Man power planning

Production material monitoring

enTIRE Retreading manages and measures all the individual items required to build a new retread, including:

- Material consumption

- Labour

- Material stock management

- Material cost used on individual casing (e.g. PLT, Repairs)

- Pre-management of casing into production based on stock availability

Figure 4 – enTIRE Retreading process management screen

Machine utilization

Detailed information regarding Station machine utilisation can be accessed including:

- Machine operational times.

- Individual casing processing cost in relate to machines utilisation cost.

- Machine maintenance schedule (under development).

Figure 5 – enTIRE Retreading in operation

Production analysis

With the ability for enTIRE Retreading to track the location of every casing and its time at each station, enormous amounts of production information can be extracted from the system including:

- Hourly factory productivity by process/shift/day/month

- Hourly station productivity by shift /day/month

- Productivity cycle time

- Individual casing detail

- Daily factory productivity report

- Daily productivity report by retread brand

- Daily productivity report by tyre size

- Monthly productivity report

- Monthly productivity report by retread brand

- Monthly productivity report by tyre size

- Processing failure rate

- Processing flow management

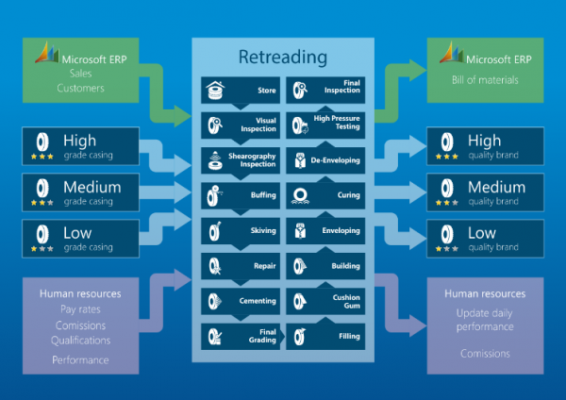

Figure 6 – Product flow management control

Multi factory and multi users

enTIRE Retreading is utilises the Microsoft SQL Server Database and is fully expandable from a single factory to a large centralised multi-factory, multi-user implementation with hundreds of online users. Multiple factories can be linked and monitored from a single location.

- Centralised Microsoft SQL database for analysis

- Multi factory management

- Multi shift management

- Remote factory process monitoring

Integration into ERP Systems

enTIRE Retreading is closely tied into the Microsoft ERP system for accounting, cost control and client management. enTIRE imports the appropriate data from the ERP to start the processing of the casing. At the end of this process, data is imported back into the ERP system to reflect the precise history of the tyre through the factory.

- Integrates into Microsoft ERP System

- Imports sales and customer information

- Imports human resource data

- Exports production performance and Bill Of Material

- Updates workers history, performance and incentives

Support and Upgrades

With a 20 year history development and support, the enTIRE range of products are used successfully throughout the world. Importantly, you investment in enTIRE Retreading means ongoing support, and assistance from us to ensure a smooth operation into the future.